In a customary laboratory setting—researchers and lab personels rely their everyday tasks massively on the laboratory equipment. With chemical hazards on the table, user safety and fume containment are the prime concerns inside the facility wherein Ductless Fume hoods or also known as Carbon-filtered enclosures take great purpose. These self-contained, advanced laboratory enclosures effectively eliminate fumes, vapors, and particles, ensuring a pristine work environment.

Fumes emanate from various processes, chemicals, substances, and reactions that can pose health risks. Effective fume containment is the art of safely capturing and eliminating these hazardous substances to ensure a secure working environment.

Understanding the principles of fume containment is the bedrock of laboratory safety. It equips professionals with the knowledge to effectively capture, control, and eliminate these noxious substances, ensuring a secure and uncontaminated laboratory environment. Moreover, a strong grasp of fume containment aids in regulatory compliance, reducing the potential for accidents, and enhancing the overall quality and reliability of scientific research. It’s the foundational step towards safeguarding both human health and the validity of laboratory findings, making it an indispensable aspect of laboratory operations.

While a variety of fume hoods exist, it’s worth noting that certain hoods may impose restrictions on the types of applications they can accommodate. Some ductless fume hoods are best suited for light-duty tasks or specific processes, while others offer versatility for handling a broad spectrum of chemicals. However, it’s crucial to remember that when working with larger chemical volumes, the lifespan of the filters will inevitably be reduced. So, it’s essential to choose the right fume hood for specific application needs while considering the potential impact on filter longevity.

POINTS TO FOLLOW WHEN USING A DUCTLESS FUME HOOD | LIST OF APPLICATIONS |

|---|---|

A limited range of various chemicals should be used. | Sample Preparation |

The recommended chemical volume should not exceed 1L per chemical. | Dilution |

No chemical with NPFA rating of level 4 in flammability and health category should be used. | Titration |

Distillation | |

Salinity test | |

Chemical handling with minimal and covered heating |

If the user’s application requirements don’t align with these criteria, opting for a conventional Ducted Fume hood is the top choice for ensuring both maximum safety and economic viability. In situations where one anticipates uncertainty regarding future chemical usage or maintains an extensive list of chemicals, conducting operations within a ducted fume hood is the best option.

It is still highly recommended to seek advice from an expert when choosing the right type of fume hood. Contact us so that we can advise you on the right type of fume hood.

Before using a ductless fume hood, it’s crucial to assess the specific needs of one’s laboratory and the chemicals to be used. Always follow manufacturer guidelines, conduct risk assessments, and provide appropriate training to users to mitigate the limitations and ensure the safe operation of the hood.

Deciding on whether to use a ductless fume hood in your laboratory and selecting the right one involves careful consideration of various factors. Such factors include assessing laboratory needs—from regulatory compliances, chemical compatibility, available space and layout, operating costs, to maintenance and after-sales services.

By carefully evaluating these factors and conducting thorough research, you can make an informed decision about whether to use a ductless fume hood and choose the most suitable one for your laboratory’s needs while ensuring the safety of your personnel and the environment.

As no extraction systems are required, ductless fume hoods potentially save more on installation costs. Since the air doesn’t have to be ducted out, it is surely an eco-friendlier option as compared to ducted ones.

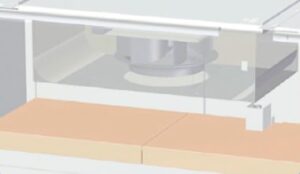

Esco ductless fume hoods are designed with a plug-and-play capability, enabling chemical containment anywhere in the building, thus making them the best option for energy efficiency, convenience, and mobility.

Below are the must-have features in a ductless fume hood:

Energy Efficiency | Excellent Filtration | Robust Hood Construction |

|---|---|---|

|  |  |

Antimicrobial Coating | Low Noise | Superior Fume Containment |

|  |  |

Centered, Angled-down Controller | Spillage-retaining Worktop | Mobility |

|  |  |

We equip your laboratory with speed and efficiency

Fill in the form and our team of experts will recommend the best viscometer and setup based on your requirements.